양극 처리된 알루미늄 판은 무엇입니까? 아노다이징 알루미늄 판은 아노다이징 공정을 거친 알루미늄 판의 일종입니다., 금속 표면에 보호막을 형성하는. 이 공정은 알루미늄 판을 전해액에 넣고 전류를 가하는 과정을 포함합니다.. 이로 인해 알루미늄 표면에 산화층이 형성됩니다., th보다 두껍고 내구성이 있습니다. ...

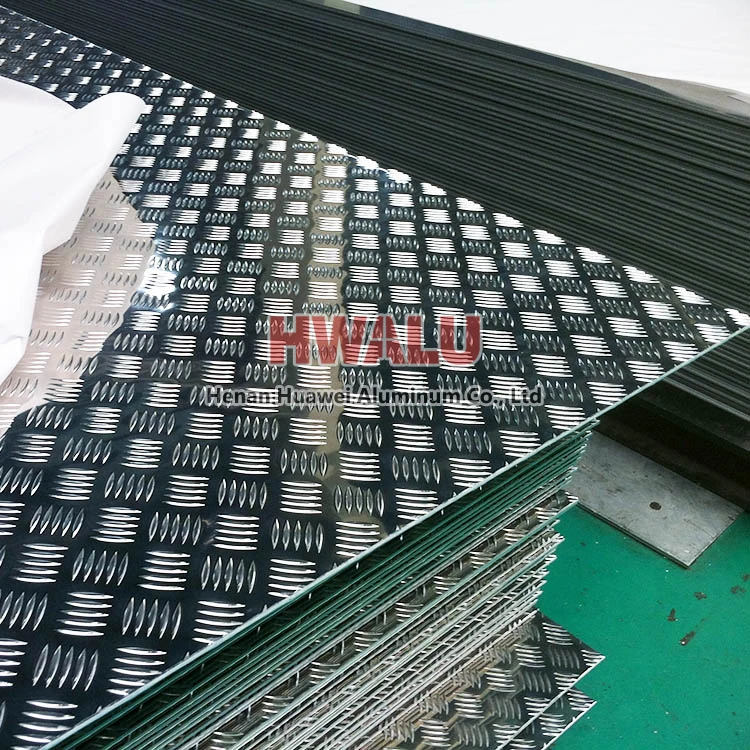

3003 합금 알루미늄 트레드 플레이트 3003 합금 알루미늄 트레드 플레이트, 다이아몬드 플레이트 또는 체커 플레이트라고도 함, 한쪽면에 다이아몬드 또는 선의 융기 패턴이 있는 알루미늄 시트의 일종입니다.. 그것은에서 만들어집니다 3003 알루미늄 합금, 내식성이 뛰어나 널리 사용되는 다목적 알루미늄 등급입니다., 적당한 힘, 좋은 성형성. 화학 성분의 3003 알류미늄 ...

양극 처리된 알루미늄 판은 무엇입니까? 아노다이징 알루미늄 판은 아노다이징 공정을 거친 알루미늄 판의 일종입니다., 금속 표면에 보호막을 형성하는. 이 공정은 알루미늄 판을 전해액에 넣고 전류를 가하는 과정을 포함합니다.. 이로 인해 알루미늄 표면에 산화층이 형성됩니다., th보다 두껍고 내구성이 있습니다. ...

알루미늄 다이아몬드 플레이트 사양: 기술:오래된 압연, 냉간 인발, Hot Rolled Thickness:0.3mm-15mm or as your requirement Width:100mm-1500mm or as your requirement Length:as your requirement Temper:영형,H111,H12,H14,H16,H18,H22,H24,H26,H32,H38,H112,T4,T6 Aluminum Diamond Plate Chemical Requirements: ALLOY Si Fe Cu Mn Mg Cr Zn Ti 1050 0.25 0.4 0.05 0.05 ...

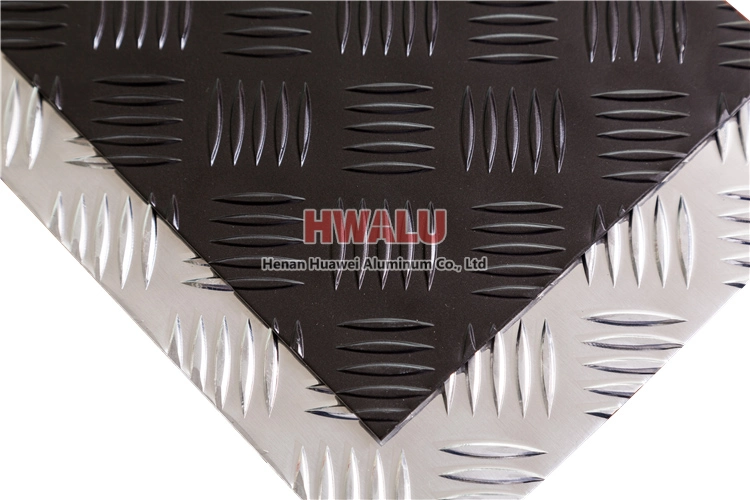

What Alloys Aluminum Tread Plate Used For Stair As the tread aluminum for stairs, 1000, 3000, 그리고 5000 시리즈 알루미늄 트레드 플레이트가 사용됩니다., 그러나 재료의 경도와 비용을 고려하여, 3000 가장 많이 사용되는 시리즈, 합금 모델에는 다음이 포함됩니다. 3003 알루미늄 트레드 플레이트, 3004 알루미늄 트레드 플레이트, 3005 알루미늄 트레드 플레이트, 3104 알루미늄 트레드 플레이트, 3105 알루미늄 트레드 플레이트, 등. 그만큼 300 ...

Ⅰ: 견적 시트--4×8 발 알루미늄 트레드 플레이트. 날짜:4월 1일 기준,2022-3월 28일 ,2022 LME 주간 평균 가격 3545 USD No. "Thickness mm" "Width*Length feet/mm" "MOQ ton" " FOB usd/ton" 1 0.2-0.29 3.27'*6.55'(1000*2000mm) 6.00 3805.00 3.93'*7.86(1200*2400mm) 8.00 4'*8'(1220*2440mm) 8.00 4.09'*8.19'(1250*2500mm) 8.00 4.91'*9.83'(1500*3000mm) 10.00 2 ...

무엇을 3000 series represent in the aluminum plate The term "3000 시리즈" 알루미늄 판과 관련하여 주로 망간을 주요 합금 원소로 포함하는 특정 알루미늄 합금 그룹을 나타냅니다.. 이 시리즈에는 다음과 같은 합금이 포함됩니다. 3003 합금, 3004 합금, 그리고 3105 합금, 루핑과 같은 범용 응용 프로그램에 일반적으로 사용되는, 측선, 그리고 판금 작업. 그만큼 ...

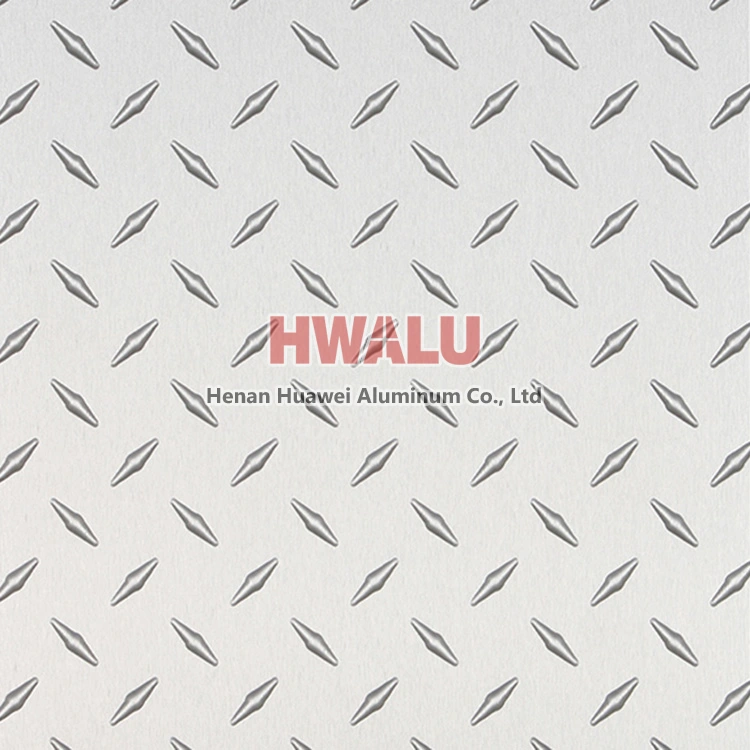

다이아몬드 모양의 알루미늄 판은 엠보싱 장비로 눌러집니다., 돋을새김된 알루미늄 판의 종류입니다. 테이블은 마름모 패턴으로 가득 차 있습니다., 특정 장식 효과로, 수하물 제조에 사용하기에 적합, 제품 포장 및 기타 산업. 등급: 1070, 1060, 1050, 1100, 3003, 3004, 5052 및 기타 재료. 4x8 다이아몬드 알루미늄 판을 알루미나 판으로 가공할 수 있습니다.. ...

Order details Product name: 3003 aluminum diamond sheet Alloy temper: 3003 h22 Size: 7feet by 7feet Pattern: 5 bars Quantity: 20 톤

무늬가 있는 알루미늄 판은 가벼운 무게와 같은 많은 장점이 있습니다., 아름다운 외모, 긴 서비스 수명, 산 및 알칼리 내식성, 및 재활용 가능성. 현재 가장 중요한 패턴 플레이트 형태가 되었습니다.. 패턴화된 알루미늄 판의 주요 등급은 다음과 같습니다. 1060, 3003, 5052, 5083, 6061, 등. 그들 사이의 주요 차이점은 다음과 같습니다: 1060 무늬가 있는 알루미늄 판 1060 가볍게 두드리기 ...

알루미늄 다이아몬드 플레이트를 칠할 수 있습니까?? 알루미늄 다이아몬드 판은 그려질 수 있습니다. 하지만, 검은색 알루미늄 트레드 플레이트를 페인팅하는 과정에는 페인트가 표면에 달라붙고 벗겨지거나 벗겨지지 않도록 적절한 준비와 기술이 필요합니다.. 다음은 알루미늄 다이아몬드 플레이트를 페인트하는 일반적인 단계입니다.: 표면 청소: 페인팅 전, 알루미늄 다이아몬드 플레이트가 깨끗한지 확인하고 f ...

아노다이징 알루미늄 체크 플레이트에 사용되는 지그는 알루미늄 플레이트를 아노다이징하는 데 사용됩니다., 아노다이징 시 지그와 공작물의 외관이 빠르게 산화피막을 생성하기 때문에, 이 과정에서 지그와 공작물이 약간 느슨해지면 접촉 방향이 변경되어 전류 흐름이 방지됩니다., 이런 이유로, 공작물을 고정하기 위해 탄성이있는 지그를 사용해야합니다.. 이 와에서만 ...