Qu'est-ce qu'une plaque en aluminium anodisé? La plaque d'aluminium anodisé est un type de plaque d'aluminium qui a subi un processus d'anodisation, qui crée une couche protectrice à la surface du métal. Ce processus consiste à placer la plaque d'aluminium dans une solution électrolytique et à lui appliquer un courant électrique. Cela provoque la formation d'une couche d'oxyde à la surface de l'aluminium, qui est plus épais et plus durable que le ...

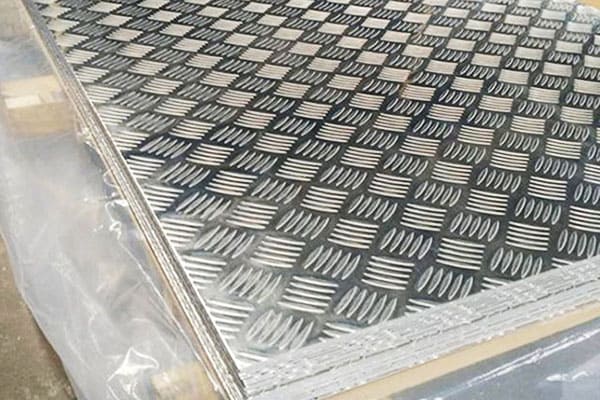

3003 Plaque de bande de roulement en alliage d'aluminium 3003 plaque de roulement en alliage d'aluminium, également connu sous le nom de plaque de diamant ou plaque de damier, est un type de feuille d'aluminium avec un motif en relief de losanges ou de lignes sur un côté. Il est fabriqué à partir 3003 alliage d'aluminium, qui est une nuance d'aluminium largement utilisée et polyvalente qui a une excellente résistance à la corrosion, force modérée, et bonne formabilité.Composition chimique de 3003 Aluminium...

Black Aluminium Checker Plate Specification Alloy: 1050, 1060, 1070, 3003, 5052, 3105, 6061 Motifs:Deux barres,trois barres,Five bar bars height: 0.8-1.3mm thickness:0.8-10.0mm width: 800-1800mm length: 800-12000mm Black Aluminium Checker Plate Chemical RequirementsAlloy Si Fe Cu Mn Mg Cr Ni Zn Ti Al1060 0.25 0.35 0.05 0.03 0.03 --- --- 0.05 0.03 99.61050 0.25 0.4 0.05 ...

Qu'est-ce que 5083 alliage d'aluminium? 5083 l'aluminium est l'un des 5000 alliage d'aluminium de série,toujours appelé alliage AlMg,Cette nuance d'alliage contient 5.0% magnésium, 0.4-1.0% manganèse et petite quantité d'autres éléments;5083 alliage d'aluminium a le poids léger, conductivité thermique et conductivité électrique de l'aluminium lui-même. En raison de la présence d'éléments Mg et Mn, la dureté et la résistance à la corrosion de 5083 Al ...

Qu'est-ce que 5 Plaque de roulement en aluminium? La plaque de roulement en aluminium à cinq barres est un type de feuille d'aluminium qui a un motif en relief de cinq barres sur sa surface, qui est conçu pour fournir une résistance au glissement et augmenter la traction. Il est couramment utilisé dans les applications où la sécurité et la durabilité sont importantes, comme les sols industriels, escaliers, marchepieds de véhicule, et surfaces de quai.Paramètres du diamant cinq barres ...

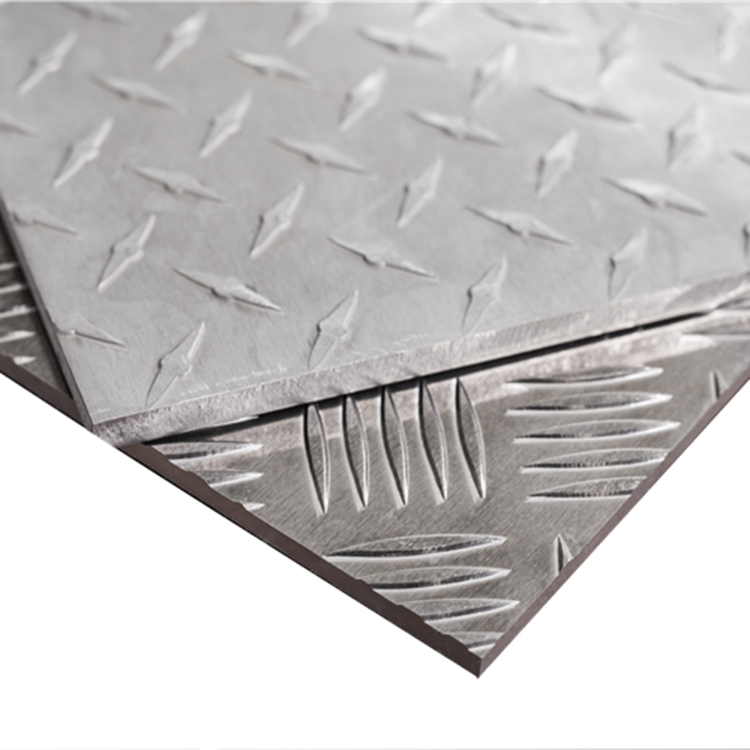

Custom Thickness Aluminum Checker Plate Custom thickness aluminum checker plate is a type of aluminum plate that has raised diamond-shaped patterns on its surface. Ces motifs offrent une résistance au glissement et empêchent le glissement et le glissement, le rendant idéal pour l'industrie, commercial, et applications résidentielles.Une tôle striée en aluminium d'épaisseur personnalisée peut être fabriquée pour répondre à des exigences d'épaisseur spécifiques, ...

Spécification de la plaque de diamant en aluminium: Technique:vieux roulé, Étiré à froid, Hot Rolled Thickness:0.3mm-15mm or as your requirement Width:100mm-1500mm or as your requirement Length:as your requirement Temper:O,H111,H12,H14,H16,H18,H22,H24,H26,H32,H38,H112,T4,T6 Aluminum Diamond Plate Chemical Requirements:ALLOYSiFeCuMnMgCrZnTi10500.250.40.050.05 ...

Pas en toute confiance: Explorez la polyvalence des feuilles d'aluminium à motifs pour la sécurité anti-skid ultime! In today's dynamic industrial landscape, sécurité, durabilité, et la polyvalence est primordial. Parmi la myriade de matériaux disponibles, La feuille d'aluminium à motifs pour anti-skid se distingue comme une solution principale pour les applications nécessitant des normes de sécurité élevées, surtout dans les industries automobiles et maritimes. ...

Libérez la durabilité: Le guide ultime pour 5052 Aluminium Tread Plates for Toolboxes Introduction In the world of heavy-duty applications, la durabilité et la polyvalence sont indispensables. Whether you're manufacturing rugged toolboxes, construire des navires maritimes, ou développer des composants automobiles, choisir le bon alliage d’aluminium est crucial.Parmi les nombreuses options, 5052 aluminium tread plates have emer ...

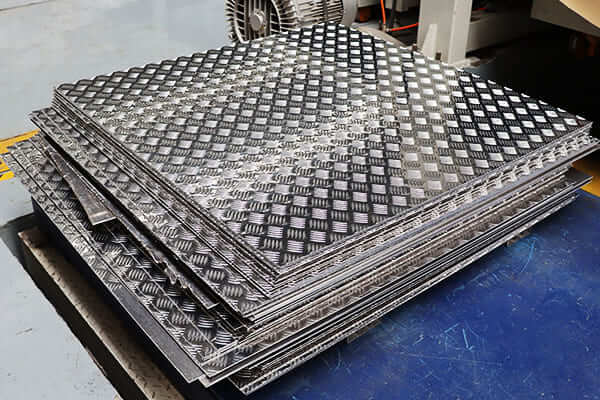

Aluminum Tread Plate 4×8 — A Practical Buyer’s Guide Introduction Aluminum tread plate 4×8 (également appelé plaque à damier ou plaque à diamant) is a patterned sheet designed to add grip, résister aux bosses, et a l'air propre en cas d'utilisation intensive.La taille 4×8 pieds convient aux camions, passerelles, sols des magasins, armoires, et murs avec un minimum de coupes et de déchets.Ce guide montre comment choisir les alliages, épaisseurs, et des modèles, what a 4×8 she ...

La plaque de roulement en aluminium présente les avantages d'une belle apparence, peut antidérapant, renforcer les performances et ainsi de suite. Les plaques de roulement en aluminium antidérapantes sont largement utilisées dans le transport, construction, décoration, plancher d'équipement, machinerie, construction navale et autres domaines. La plaque de traitement en aluminium est un coût élevé des matériaux modernes, il existe de nombreux types, il a un large éventail d'applications dans les meubles, comme les réfrigérateurs, ...

Aujourd'hui, de nombreuses industries ont besoin d'utiliser des plaques d'aluminium à motifs en grande quantité. Il a une large gamme d'applications et est très pratique. Compartiments de camion particulièrement grands, conception de navire, appareils ménagers, etc. utiliser essentiellement ce type de plaque d'aluminium, mais le niveau technique de chaque constructeur est différent, et la qualité de la plaque d'aluminium est également complètement différente. Laisse-moi t'expliquer quoi ...